Dry and pre-action sprinkler systems can be especially susceptible to early failure due to internal pipe corrosion. As the old saying goes, "An ounce of prevention is worth a pound of cure." NFPA 13, Standard for the Installation of Sprinkler Systems, gives the minimum "prevention" steps for preventing corrosion. NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, Chapter 14, gives the minimum "pound of cure."

Draining Sprinkler Pipes

Preventing corrosion starts with good installation practices. NFPA 13 (2013) section 8.16.2 outlines the minimum requirements for draining sprinkler systems, including main and auxiliary drains, and requiring slope on piping.

This table summarizes the pipe pitch (slope) requirements:

|

System Type |

Branch Line Pitch |

Main Line Pitch |

|

Wet Pipe |

No Slope Required |

No Slope Required |

|

Dry Pipe and Pre-Action |

½" drop over 10' of run |

¼" drop over 10' of run |

|

Dry Pipe and Pre-Action in Refrigerated Areas |

½" drop over 10' of run |

½" drop over 10' of run |

NOTE: Prior to 2007, NFPA didn't require pitching of pipe in pre-action systems not subject to freezing. Systems installed before 2007 most likely have a significant amount of trapped water.

Installing a system with a pitch can be difficult and requires a lot of advanced planning and ceiling space for the vertical room required. Long runs of pipe may have to change the pitch multiple times in order to fit within the vertical space p

rovided, causing traps of water within the system. Finding a long, unobstructed space to route pipes is rare, and pipes must often offset over or under ducts or other obstructions, every time creating a spot where water can pool.

Section 8.16.2.2.2 requires that any trapped piping (low points in the system) must be provided with auxiliary drains. Section 8.16.2.5 requires an auxiliary drain in locations where a change in piping direction prevents drainage through the main drain valve. That section goes on to give requirements for size and arrangement of the drain valve based on the volume of trapped water.

Assessing for Obstructions

NFPA 25 (2014) 14.2.1.1 requires that every five years an assessment of the internal condition of metallic sprinkler piping be performed. The purpose of the assessment is to inspect for the presence of foreign organic and inorganic material. Sometimes during this inspection evidence of Microbiologically Influenced Corrosion (MIC) can be found as well as indication that foreign material is present in sufficient quantity to obstruct the pipe or sprinklers.

If evidence of obstruction is found, NFPA 25 requires that an obstruction investigation be performed. The items below are confirmation that corrosion or MIC may be present in the system:

- The discharge of obstructive material during routine water tests.

- Foreign materials in fire pumps, in dry pipe valves, or in check valves.

- Foreign material in water during drain tests or plugging of inspector's test connection(s).

- Unknown materials are heard in the system piping during draining, refilling, or otherwise flowing water through the system.

- Plugged sprinklers.

- The presence of sufficient foreign organic or inorganic material is found in the pipe.

- Pinhole leaks.

- A 50 percent increase in the time it takes water to travel to the inspector's test connection from the time the valve trips during a full flow trip test of a dry pipe sprinkler system when compared to the original system acceptance test.

Dealing with Obstructions and MIC - A Pound of Cure

It is possible to deal with the presence of MIC. Some options would be:

- Install plastic sprinkler pipes

- Treat all incoming sprinkler water with biocides

- Regularly check for corrosion and blockages

- Develop a treatment plan to replace of affected pipe or flush obstructions

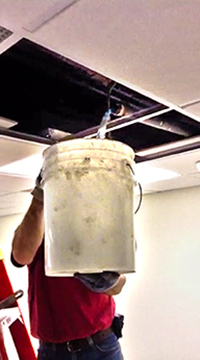

Flushing a sprinkler system where blockages have been found can be done, but is difficult. Annex D of NFPA 25 has valuable information about performing system flushing. In general, a lot of water must be pushed through the pipe to remove scale and buildup. Unless caution is used, the interior of the building and its contents are at risk of accidental water damage. Cleanup of discharged water can also be a hassle.

Many times internal pipe assessments may reveal that pipe has been damaged by corrosion to the point it must be replaced. This can be very costly in an operating building.

Nitrogen Generators - An Ounce of Prevention

Building owners and engineers should understand the risks for corrosion in dry and pre-action sprinkler systems. Many problems can be avoided by the installation of a nitrogen generation system. Nitrogen generators have many benefits in extending the useful life of your sprinkler system, eliminating MIC, and reducing the risk of a catastrophic leak developing in your system.

Many times, a system protected by nitrogen will overcome installation issues where pipes can not be properly drained.

Want to learn more on this topic? Click here and schedule your FREE Lunch and Learn. An ORR expert will come to you and train you and your team on your choice of fire protection topics including corrosion prevention in dry pipe or pre-action sprinkler systems. Lunch is on ORR.