To ensure the nitrogen generator is adequately sized, the following information is required:

STEP 1: SELECT A NITROGEN GENERATOR

To ensure the nitrogen generator is adequately sized, the following information is required:

1) The total cumulative size of all dry/preaction sprinkler systems

2) The size of the largest single dry/preaction sprinkler system

3) The total number of dry/preaction sprinkler systems

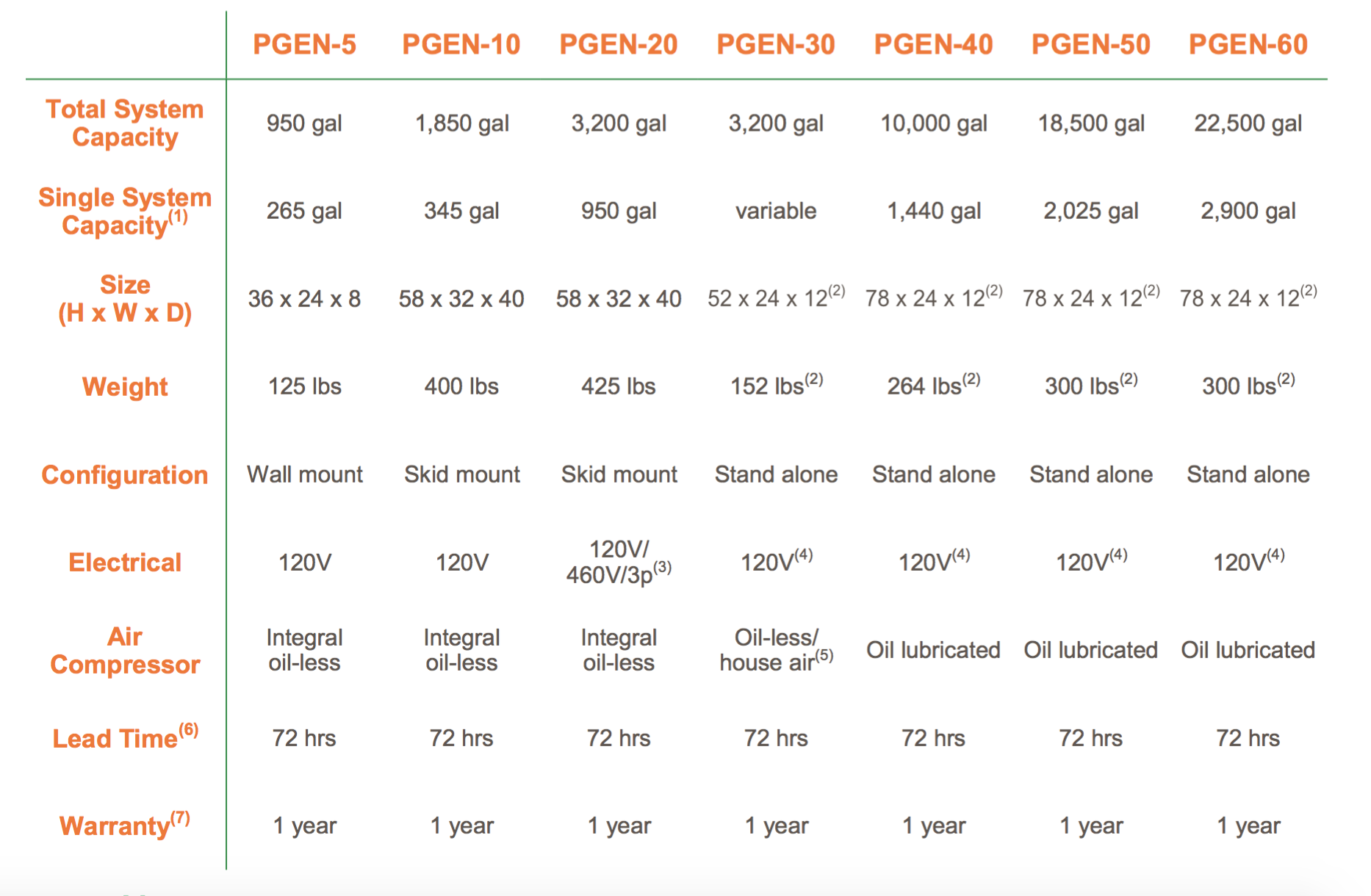

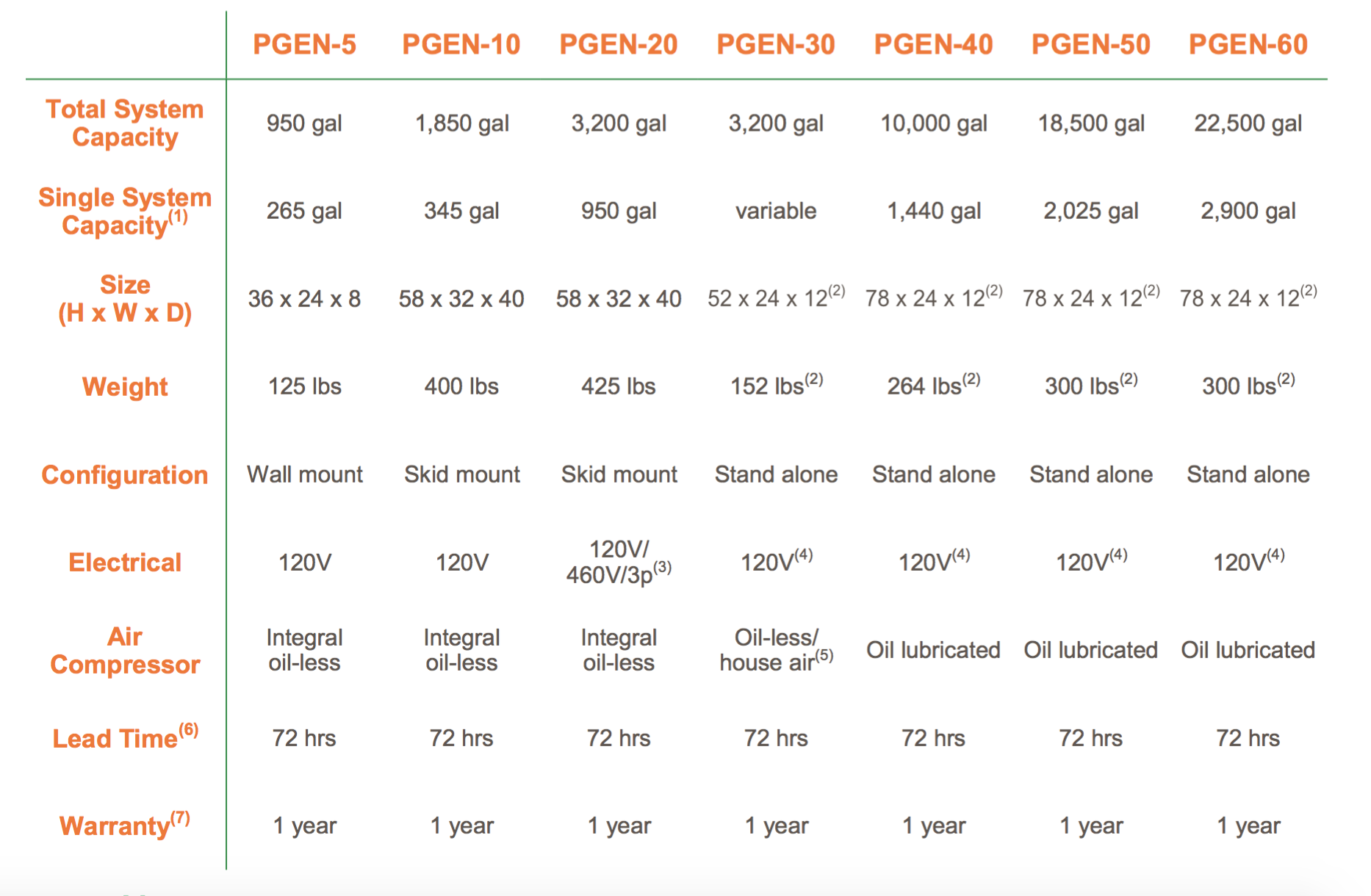

With this information an ECS nitrogen generator can be selected. Small to medium projects can generally be supplied with a pre-engineered nitrogen generator that includes an integral air compressor (PGEN-5/10/20). Projects with a larger cumulative sprinkler system capacity should be supplied with an engineered stand-alone nitrogen generator paired with a separate air compressor (PGEN-30/40/50/60).

STEP 2: SELECT A VENT

To facilitate the removal of oxygen, ECS utilizes the patented “fill and purge” breathing process which requires installation of a vent to control gas discharge from the fire sprinkler system. One (1) vent is required on each dry/preaction fire sprinkler riser, with two available options:

1) ECS Protector Manual Vent (PAV-D)

2) ECS Protector Dry SMART Vent (PSV-D)

The PAV-D is a mechanical device that is closed manually once the system nitrogen concentration has been verified at 98% or greater and represents the most economical approach to oxygen removal. The PSV-D includes an electronic sole- noid valve that closes automatically once the desired nitrogen concentration has been reached and is preferred in applica- tions that value automation or minimal human intervention.

STEP 3: SELECT MONITORING EQUIPMENT

Engineered Corrosion Solutions believes that a true corrosion management system should be monitored for performance to ensure that fire sprinkler system piping is properly protected against oxygen corrosion. ECS offers multiple monitoring options to pair with a nitrogen generation system:

STEP 4: CONTACT ORR PROTECTION SYSTEMS

NOTES:

- Single system capacity based on 30 min. fill requirement of largest single sprinkler system at 40 psi; a secondary air compressor with normally closed isolation valve can be used to meet fill requirement for larger individual systems

- Size and weight of nitrogen generator only, does not include separate air compressor

- 120V power supply required for nitrogen generator, 208 or 460V/3 phase power supply required for compressor

- Power requirement for stand alone nitrogen generator only, does not include separate air compressor power requirements, options include: 200V/230V/460V 3 phase

- PGEN-30 designed to receive air from oil-less compressed air supply only

- Lead time refers to time from order receipt to shipment from ECS facility, does not include shipping time

- Per ECS terms and conditions