Chemguard’s engineered and manufactured foam fire suppression systems ensure a rapid, thorough, and economical response to fires and spills. Customized to application specifications, our dependable engineered systems include bladder tanks and pump-type balanced-pressure proportioning systems; in-line balanced-pressure proportioning systems; high-expansion foam systems; large dry chemical systems and skids; twin-agent systems and skids; foam trailers; large dry chemical and twin-agent trailers; monitor trailers; aqueous film-forming foam (AFFF) pump systems; water-powered AFFF pump skids; foam/water monitors; nozzles; eductors; ratio-flow controllers; foam makers; foam chambers, and specialized proportioning storage and monitor trailers.

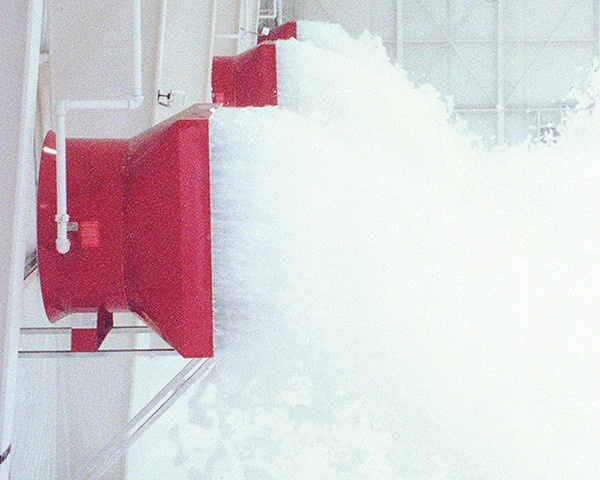

Chemguard UL Listed high-expansion foam systems provide fire-fighting protection for diverse applications: aircraft hangars; basements; cable tunnels; flammable packaging areas; flammable liquid drum storage areas; hazardous waste facilities; LNG tank farms and loading facilities; mines; roll-paper warehouses; shipboard engine rooms, bilges, and holds; storage buildings; warehouses; and wildland fire breaks. The light, voluminous foam blanket produced by our high-expansion foam systems can quickly obtain great heights, reaching elevated flammable materials (such as on storage racks). The foam blanket efficiently transports small amounts of water to the fire, encapsulating the flammable vapors and causing suppression and extinguishment.

Chemguard foam systems can be designed and engineered for specific applications, such as use in harsh environments. In addition, many components are available as replacement parts (or improvements) for existing systems.