Venting And Pressure Control Devices

ECS Protector Manual Vent (PAVD)

- Facilitates patented "fill and purge” breathing process

- Sprinkler system reaches 98% nitrogen within two (2) weeks

- Installed at fire sprinkler riser, no remote installation required

- Pressure regulator prevents system depressurization

- Float valve prevents water discharge

- Requires no plumbing to drain

- No electric required

ECS Protector Dry SMART Vent (PSV-D)

- Facilitates patented “fill and purge” breathing process

- ECS Protector Dry SMART Vent

- Automatically closes once 98% nitrogen has been reached

- Installed at fire sprinkler riser, no remote installation required

- Pressure regulator prevents system depressurization

- Float valve prevents water discharge

- Requires no plumbing to drain

- Includes control box enclosure, requires 120V power supply

ECS Protector Nitrogen Interface Controller (NIC-1)

- Allows one nitrogen source to supply multiple sprinkler systems operating at different pressures

- Allows one nitrogen source to supply multiple sprinkler systems operating at different pressures

- Facilitates patented “fill and purge” breathing process when paired with a venting device

- “Plug and Play” performance in self-contained wall mount cabinet

- Includes manual bypass for fast fill option

- Requires 120V power supply

Notes

- One (1) venting device required per sprinkler system, vent assembly requires 1/2” connection at riser

- Install Dry SMART Vent control box on wall adjacent to vent assembly installed at riser

- Nitrogen Interface Controller only required for multiple dry/preaction systems supplied from one nitrogen source and operating at different pressures, not required for multiple dry/preaction systems operating at a single maintenance pressure

Monitoring Devices

ECS In-Line Corrosion Detector (ILD)

- Only device that provides continuous real-time corrosion monitoring of a fire sprinkler system

- Matches size, schedule, and material of system piping

- Provides 360° surface area to detect internal corrosion

- Thin wall section monitored by UL Listed/FM Approved pressure switch

- No obstruction risk and no replacement coupons used

- Includes remote test station, can be monitored remotely and with fire alarm or building automation systems

ECS Protector SMART Gas Analyzer (SGA-1)

- Provides continuous real-time gas concentration of system

-

Multiple signal outputs: contact closure, 0-5V DC, and 4-20mA

-

Can be monitored by fire alarm or building management systems

-

Includes digital display

-

Accepts 24V DC or 120V AC power supply

-

Paired with ECS venting device for continuous gas supply

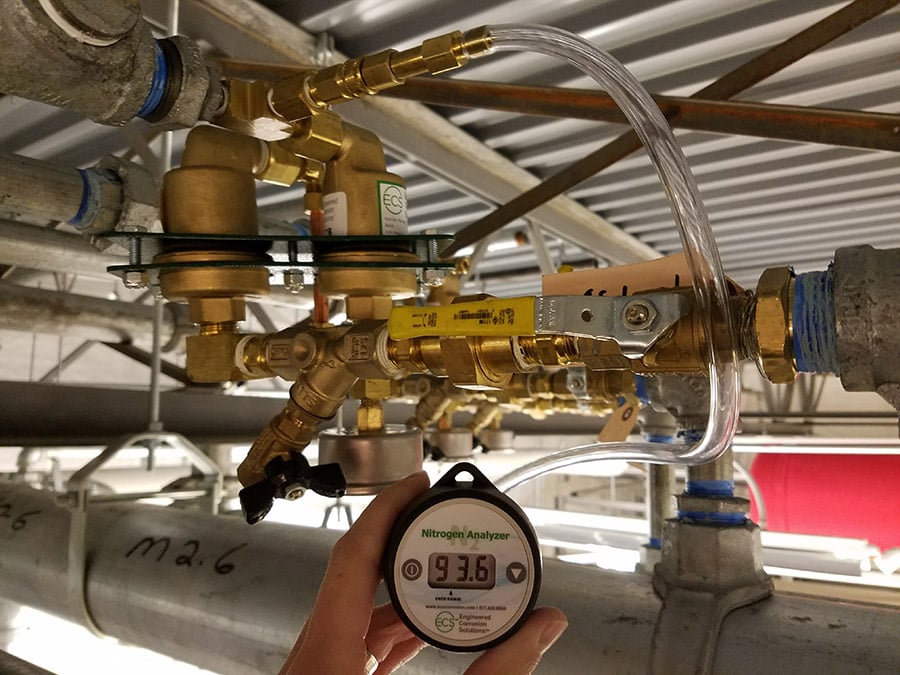

ECS Protector Handheld Gas Analyzer (PHGA-1)

Notes

- At least one (1) In-Line Corrosion Detector recommended per nitrogen generator

- In-Line Corrosion Detector typically installed on dry/preaction system mains where trapped water collects

- One (1) SMART Gas Analyzer recommended per nitrogen generator, must be installed adjacent to ECS venting device

- Pressure rated gas sample tubing between venting device and gas analyzer provided by ECS